machining surface finish chart

What machining CNC surface finishes does Hubs offer. Still it has significant flaws that make.

Machining surface finish Surface finish is another term for surface roughness.

. Surface finishes may be increased to 16 08 to. You can use an abrasive or sand the surface as a. Surface finish also known as surface texture or surface topography is the nature of a surface as defined by the three characteristics of lay surface roughness and waviness.

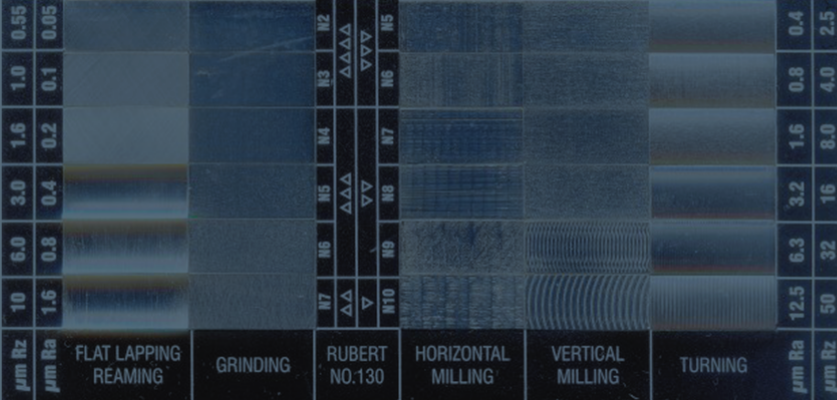

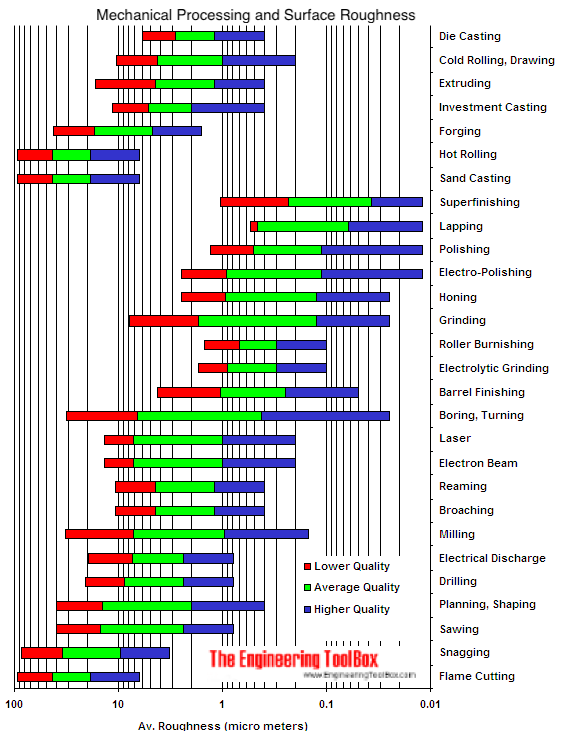

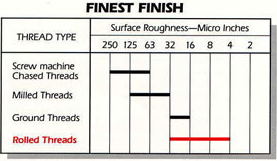

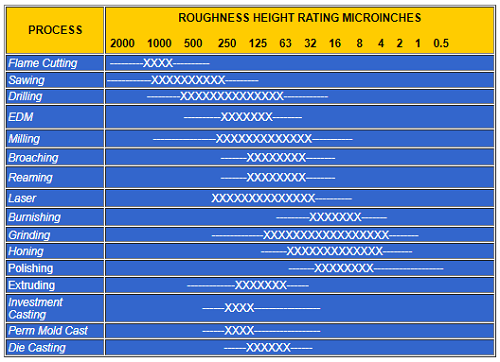

The surface finish is put forward according to the human visual point of view. Surface finish Chart by Machining Technology In the below chart you can find out the lowest surface roughness best surface finish that the main machining processes can achieve. Finish Symbol N Finish R a μinch R a μm Super finishing.

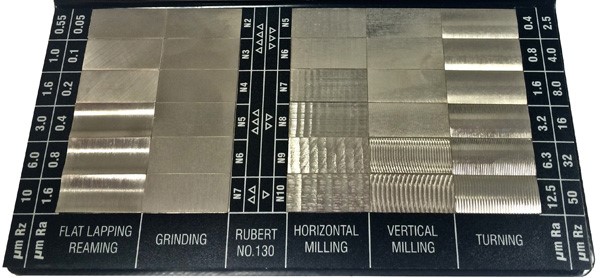

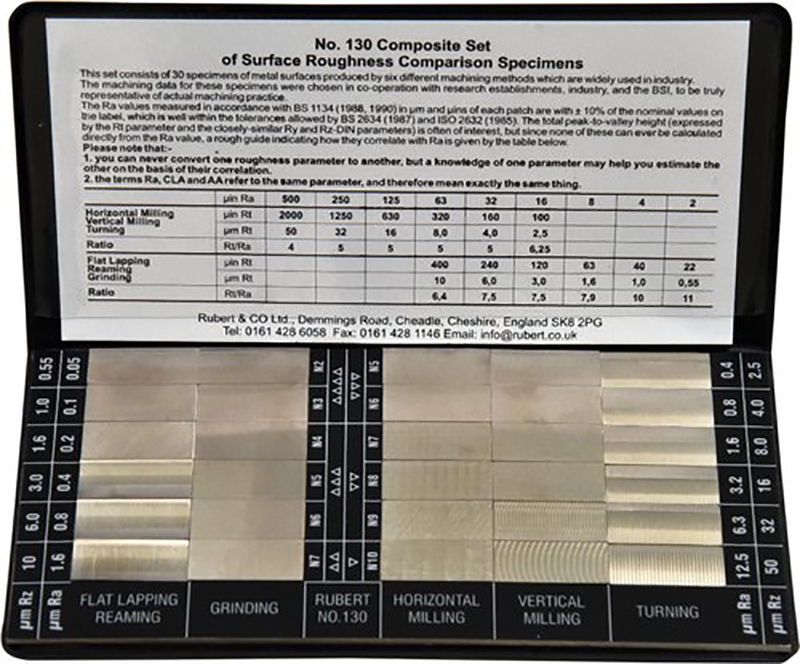

Manufacturers always use it as reference material to ensure quality in the. Moreover the Ra surface finish chart is commonly utilized for absolute values when describing measuring and duplicating surface topology. 500 8 Supermirror Finish 4 3 - 8 500 8 Supermirror Finish 4 01 16 04 4 - 10 N3 Buff 400 2 006 8 02 N2 1 0025 4 01 N1 C SURFACE FINISH CROSS REFERENCE CHART Common USA.

Minorly visible tool marks with a standard surface roughness Ra of 32μm. Ra Roughness average in micro-meters micro-inches. Table of Contents.

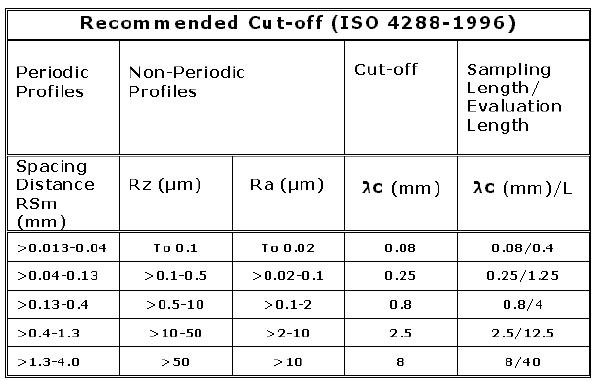

Surface roughness is a measure of the total spaced irregularities on a parts surface. The machining surface finish chart offers important guidelines for measuring standard surface finish parameters. Machining N9 250 63 N10 500 125.

The following charts and tables convert surface finish or roughness between selected industry standard units. What is the plastic surface finish chart. Yide Casting is a leading iron foundry provide both casting service and machining service equipped.

Please note that these are all for metal parts. Surface Finishing in CNC Machining with Symbols Charts RZRA Roughness ExplanationsStandards. The surface finish comparator for milling turning reaming and grinding.

Here are the most common surface finishes available on the Hubs platform. This is what engineers and machinists mean when. N1 1 0025 Lapping.

The plastic surface finish chart is a guide to the various finishes that can be applied to plastic parts. SURFACE FINISH COMPARISON CHART. Sanding polishing the 3D printed parts is simple but needs focus on details step by step from 100-200 grit sandpaper or grinder to remove stepping lines then gradually.

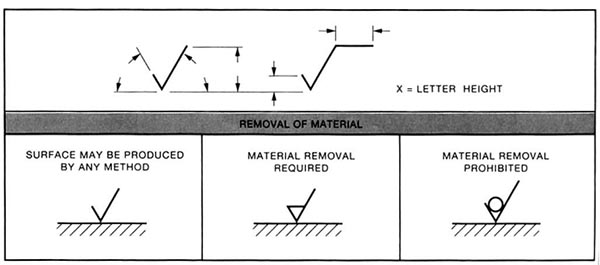

The chart lists the name of the finish the. Different types of lay patterns. RA is the arithmetic average deviation of the surface valleys and peaks and is often used to specify the roughness of a machined surface.

15 rows Surface finish specification and comparison.

Cut Offs And The Measurement Of Surface Roughness Spectrum Metrology

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Surface Finish Specifications And Their Hidden Cost Impacts Keller Technology Corporation

Surface Roughness Vs Mechanical Processing

Average Roughness Basics Michigan Metrology

Basics Of Surface Finishing With Pdf What Is Piping

What Is Surface Finish Units Symbols Chart Engineering Choice

Cnc Machining Surface Finishes Introductions Cnc Surface Roughness Texture Topology Finishing

Thread Rolling Cold Formed Metal Parts Cold Formed Threads Cold Heading

Surface Finish Surface Roughness It S Indications Symbols

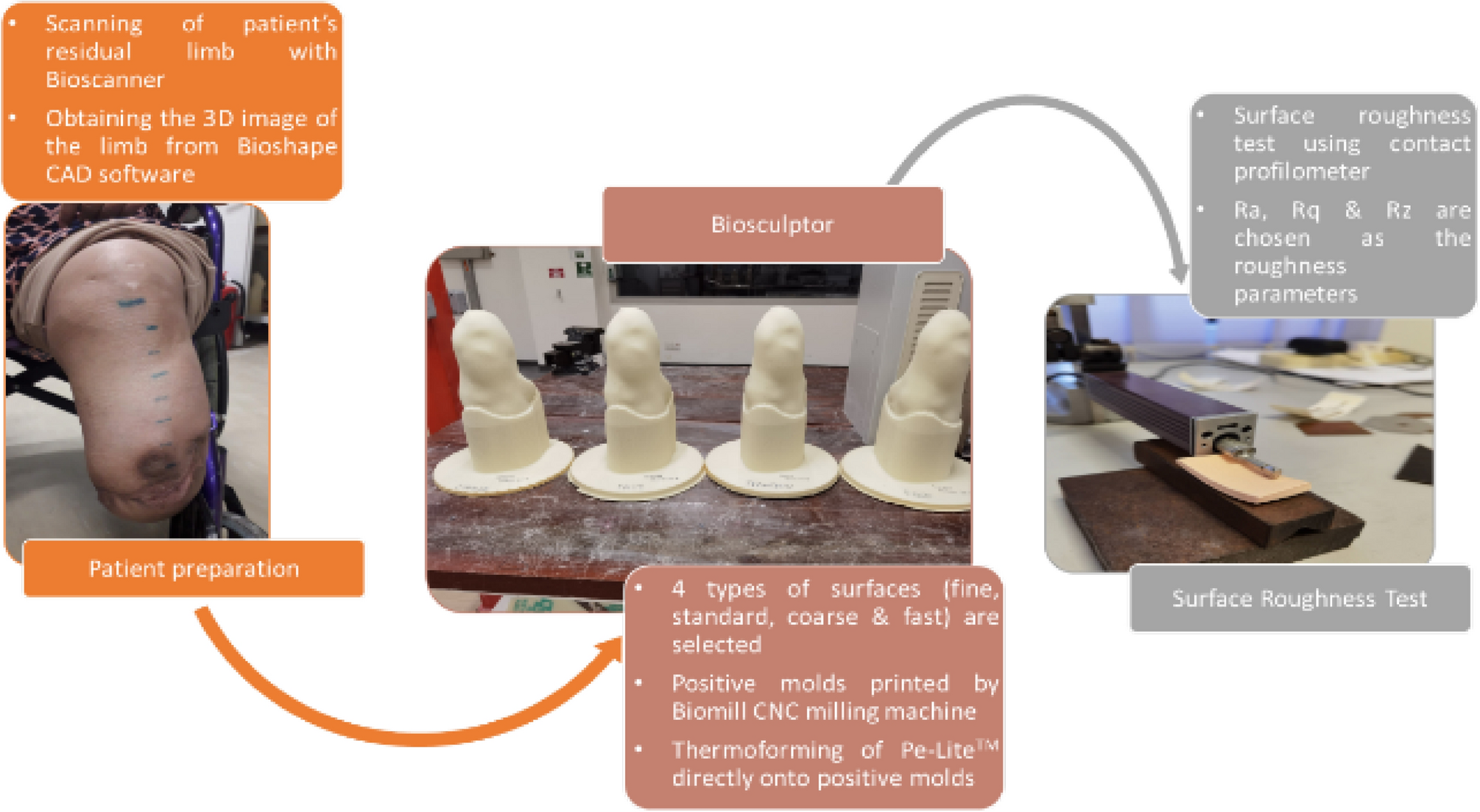

Validation Of A Roughness Parameters For Defining Surface Roughness Of Prosthetic Polyethylene Pe Lite Liner Scientific Reports

Machining Surface Finish Chart Conversion Comparator Method Degree Ra Rz Rms

Surface Roughness Finish Review And Equations

Surface Finish Quality Ra Rz Rt Surface Roughness Measuring Finish

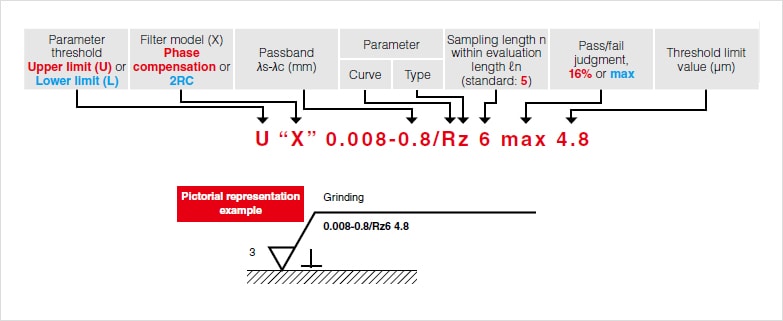

Understanding Surface Roughness Symbols Introduction To Roughness Keyence America

Surface Finishing Basics Fractory